NEW VILITER car

Discover all the advantages of the perfect car

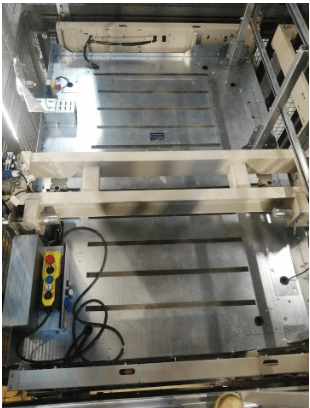

New floor design

more robust and with a waterproof and fireproof wooden base improving passenger comfort in the car in case of rubber or sheet metal flooring. We have also improved the finish quality thanks to a new rubber gluing process. On marble flooring, the minimum pit required is reduced by 20 mm.

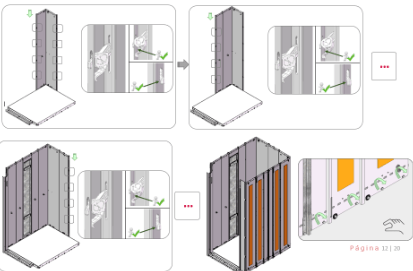

New panel joining system

which increases the rigidity of the walls and allows the car to be assembled by a single person from the inside. The assembly is carried out slat by slat, quickly and easily. An external suction cup is required for assembly.

New roof design

in galvanised steel without welds to create a completely open work surface. The roof is supplied on lifts with our MP ecoGO controller pre-wired through the inside of the lift for quicker and easier installation. The handrails have been redesigned, increasing their strength and making them easier to assemble. In addition, a new, more compact inspection box has been added, making it easier to locate on the car roof. The new magnet locking system provides easier maintenance work.

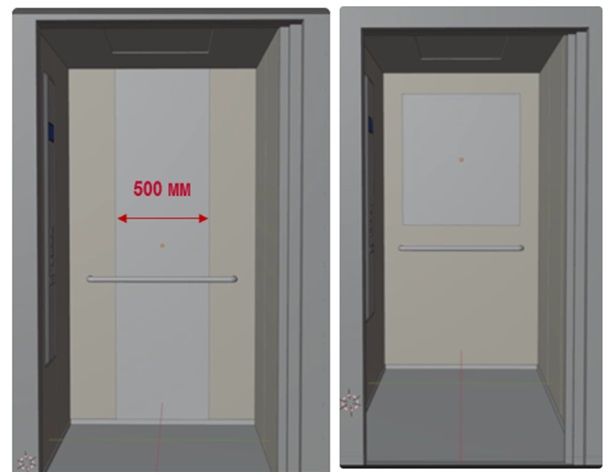

Aesthetic and functional improvements of mirrors

We improved the aesthetics of the panel model, increasing the width from 300 to 500 mm. In future versions we will also introduce a new model of small partial mirror. In addition, all models incorporate a new fixing system, by means of stainless-steel profiles, allowing the mirror to be easily removed in the event of breakage without the need to dismantle the panel or break the glass.

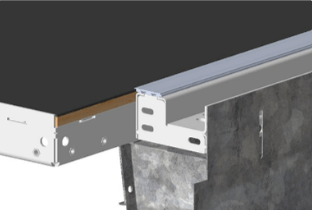

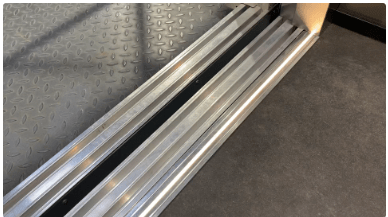

New aluminium extension

New aluminium extension for the connection to the car sill for a cleaner finish. In future versions, a decorative car lighting option will be available, which will include a LED strip in this profile.

New lighting panels

screwed to reduce vibrations in the car. We will renew the range with new models in future versions. You can already order them via comments.

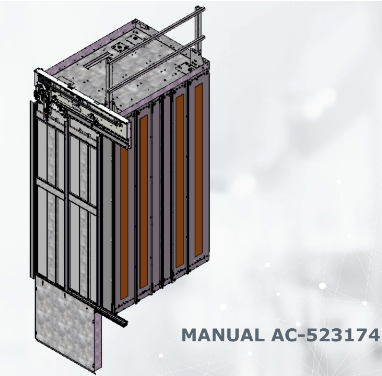

New parametric 3D design

Manufactured per order and simpler assembly manual for every car, which minimises the chance of installation errors. All components such as balustrade, inspection box, etc. are positioned in their accurate location.

New two-pack packaging

The floor is supplied in a separate package to suit the assembly sequence better. The rest of the car is supplied in a second, smaller package for easier handling on the job site.

Weight reduction of around 5%

which further minimises the environmental impact.